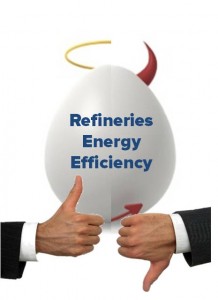

Less is more is a concept that is generally lacking in the field of engineering where the design philosophy seems often to make things more complex than they need to be.

I was reminded of this during a recent project for an oil refining client in the Middle East. It was the design of a piping system at the bottom of a column for transferring a stream through a series of heat exchangers into a downstream furnace. By well- established convention, the system would be designed for the highest possible flow rate and pressure drop of the system, with an allowance of an additional 30% of the total pressure drop for the control valve. This sets the pump (usually a centrifugal pump) differential pressure requirement.

If the pump was selected according to the commonly used API 610 standard, it would have to develop the differential pressure with an impeller diameter of 90% of maximum – to allow for possible future debottlenecking. The pump manufacturer would then offer the next frame size up in his range. All of this additional “up-sizing” would pile on the inefficiencies. Continue reading…